Add Fusing Glass Bubbles

To Fused Glass

Fusing glass bubbles can be formed in fused glass by placing copper oxide (cupric oxide) powder between layers of clear art glass.

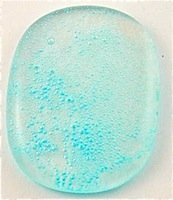

When fused in a glass fusing kiln the powder will produce turquoise colored bubbles as per the above photo.

Copper oxide is used in ceramics to produce certain red, blue and green glazes and is available from ceramic supply stores.

The powder can also be found in a small number of art glass supply stores.

Applying Copper Oxide

Normal safety precautions should be observed when working with copper oxide.

Face mask, gloves and protective glasses should be worn.

When spraying copper oxide always work in a well ventilated area.

Spraying

The above photo shows a fused glass piece that has been sprayed with a mix of copper oxide and distilled water.

The powder and water should be mixed until a fine black film is sprayed onto the glass. A small hand operated pump action spray was used to spray the mixture.

The sprayed mix must be even and thin on the glass or else it won't work.

It should be dry before the glass cap is fitted.

The glass is fully fused in a warm glass kiln. As this was a small piece of glass, it was fused very quickly and then allowed to cool to room temperature in the glass kiln.

Sifting

Copper oxide can be lightly sifted onto fusing glass with a fine sifter, if the powder begins to clump shake from glass and start again.

Only a very light even coating is needed otherwise the result will be a very uneven patchy look with very few bubbles.

The photo below shows a fused glass piece that has had copper oxide powder sifted onto the glass and then covered with a clear glass cap.

The same glass fusing procedure as outlined above was used for this example.

Air Brush

For larger areas, a compressor driven air brush can be used to apply a mix of powder and distilled water.

A very fine even coat can be applied this way, resulting in a nice coverage of bubbles and color after the glass fusing process.

Plates and bowls are suitable for spraying, very effective results can be achieved on large areas.

Ensure safety equipment is worn when spraying. Spray in a well ventilated area.

Return From Fusing Glass Bubbles To The Glassworks

Return To Home Page