Fusing Bubbles Forming In

Glass Projects

During the kiln forming process fusing bubbles can form in the heated glass.

For some artists this may be acceptable, other glass artists prefer not to have any fusing bubbles at all.

Sometimes an unfired sheet may already have some present when you purchase it. These cannot be removed.

Avoid buying this kind of glass in future.

Possible Causes

• trapped air between glass layers

• trapped air between glass and kiln shelf

• trapped air between glass and mold

• air trapped around inclusion

• reaction between an inclusion and the glass

Kiln Shelf

If air is trapped between the kiln shelf and bottom of the glass, it will increase in size until it pops, leaving a hole behind that may be too big to fix.

This problem can be the result of an uneven kiln shelf.

Check the shelf with a ruler or straight edge; turning the shelf over will sometimes fix the problem. Other wise replace the shelf.

Using fiber paper between the shelf and the glass can also prevent this happening. Air is able to escape through the fiber paper.

Air Between Layers

Another way to deal with fusing bubbles is to fire to a lower temperature, holding the glass there longer,

Firing to 1450 F to 1464 F (788 C to796 C) hold for 20 minutes or longer.

If bubbles are present in a kiln fired piece you can sometimes use an awl to break them, place frit around the hole without covering it completely, refiring to recover your piece.

Be careful with colored frit as the color may vary even if it’s from the same maker.

When laying out your art glass piece prior to firing in your glass kiln try to keep a space between the elements of your design so that the air may escape.

Bubble Squeeze

To avoid A problem occurring between glass layers it helps to include a bubble squeeze in your firing schedule.

This is a slow down of the firing rate and the inclusion of an additional hold during the fusing cycle.

The idea being that air will be slowly expelled from between the glass.

Glass Mold

Many glass fusing molds have small air holes to allow air to escape. Always check to ensure that kiln wash is not blocking the holes.

Inclusions

Air can be trapped around inclusions causing bubbles.

It is possible to use the the cutting method outlined in the second last segment of this page to overcome the problem.

If a chemical reaction occurs between the inclusion and the glass a hole may appear in the glass surface resulting in the scrapping of the item.

Fused Glass Jewelry

Fusing glass jewelry can also present bubble problems.

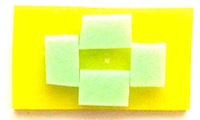

The exaggerated mock up in the photo below shows a jewelry piece with the top layers all touching.

If a glass cap is placed over this the air will not escape and a bubble will form.

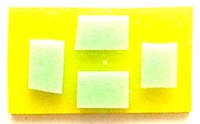

This exaggerated photo shows the pieces separated to allow air to escape from under a cap during the glass fusing phase.

Another way to handle this, if the top elements must touch, is to cut the base glass layer and fire the piece slowly on fiber paper.

The air will escape through the bottom layer and the fiber paper.

Sometimes small pieces of frit can be used to support the edges of the cap on art glass jewelry to allow air to escape.

The same method can be used on larger pieces of fusing glass by using tiny pieces of glass to support the glass edges.

Firing Schedules

Correct firing schedules will assist greatly in bubble control

I use a piece of software called EZ Fuse to calculate firing schedules.

This software will determine schedules for a range of glass

brands and coe's. It will calculate by size and layers as well as the

type of kiln being used.

Return From Fusing Bubbles To Fusing Problems

Return To Home Page